Previous

Next

About Us

Temekna represents Gambarotta Gschwendt part of Gambarotta group and we also deal with European equipments for bulk material handling solutions. Temekna has established and enjoy a very positive reputation across our business. Our reputation influences so many aspects of our company – the way our customers feel about our products and services how regulators perceive us; and whether employees find Temekna a satisfying place to work. Therefore, it is important for all of us to protect our reputation through a strong culture of integrity and ethical conduct.

Our Products

-

TTP – Deep Bucket Conveyors

Read more -

TRS – Drag Chain Conveyor with Single Drop Forged Chain

Read more -

TRP – Scraper-Paddle Conveyor

Read more -

TRLC – Cleaning Drag Chain Conveyor

Read more -

TRL – Cleaning Drag Chain Conveyor

Read more -

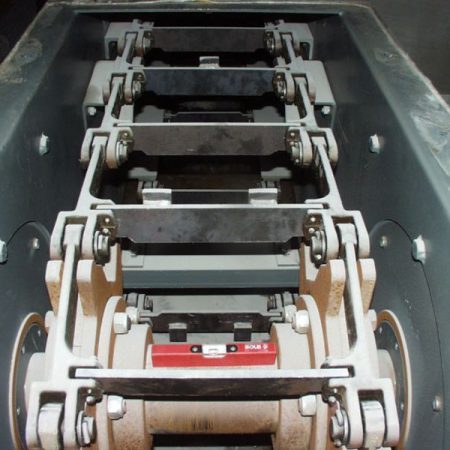

TRD – Drag Chain Conveyor With Double Chain

Read more -

TRC – Submerged Drag Chain Conveyor

Read more -

TRA – Drag Chain Conveyor

Read more -

TPT – Pan Conveyors with Baffles

Read more -

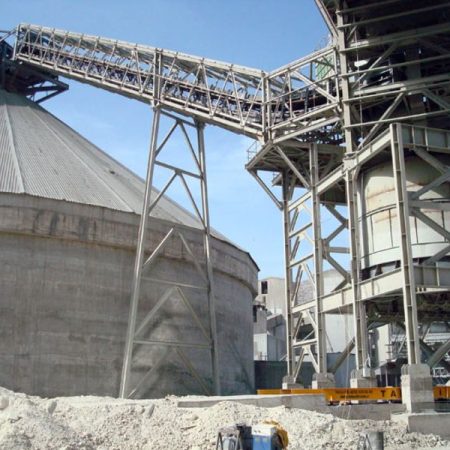

TPL – Long Pan Conveyors

Read more -

TP – Pan Conveyors

Read more -

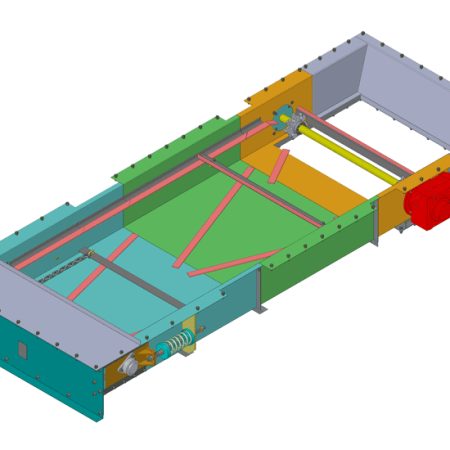

TC – Box Conveyors

Read more

Contact

If we can help you with any further information, please use the contact form to get in touch.

You will receive an immediate automated acknowledgement, and we will respond to your enquiry as soon as possible.

Many thanks

[wpforms id=”636″ title=”false” description=”false”]

Get Connected

Facebook-f

Twitter

Instagram

Envelope

About Us

Temekna has established and enjoy a very positive reputation across our business.

Navigation

Contact Us

- Punjab Expeller Compound, Plot No. 5, Gali No. 6, Meerut Rd, Near Blue Dart Office, Ghaziabad, Uttar Pradesh 201003

- info@temekna.in

| Copyright Ⓒ 2022 TEMEKNA |